SMC (Sheet Moulding Compound) water tanks are made of a composite material consisting of thermosetting resin, glass fibers, and mineral fillers. The material is molded into panels and then assembled to form a water tank of the desired size and shape.SMC water tanks are durable, lightweight, and resistant to corrosion, making them ideal for outdoor and indoor applications, such as residential, commercial, and industrial water storage.

If you have specific questions about SMC water tanks or need details on suppliers and manufacturers, feel free to ask!

GRP (Glass Reinforced Plastic) water tanks are also made of composite material, but they use a different manufacturing process. GRP tanks are made of layers of fiberglass reinforced with resin and formed into a seamless, one-piece vessel. Like SMC tanks, GRP tanks are lightweight and durable, and they are also resistant to corrosion and UV radiation. They are commonly used for industrial applications, as well as for residential and commercial water storage.

GRP module water tank is a new type water tank after the development of reinforced concrete water tank , steel plate water tank, stainless steel water tank.GRP water tank combined with the GRPmolding panel, sealing materials, metal structure and piping system to onsite assemble together.

SMC Water Tanks satisfy relevant Food Sanitation standards. Since exterior light is completely blocked, bacteria generation and germ growths are prevented. In particular, when large panels are employed, existing water tank interior structures are eliminated, allowing long-term sanitary use of water tanks.

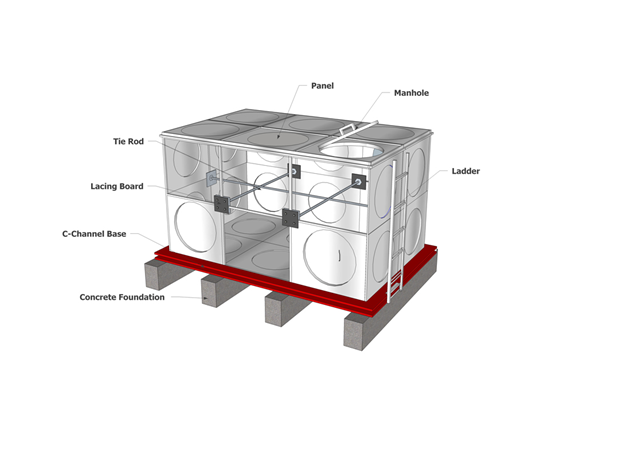

The interior structural components of a water tank consist of Storage Tank System (STS) and Base Layer (STS PE coating and Winding Pipes) that prevent corrosion or rusting. The external components are Melt Zinc plated, thus having semi-permanent useful life.

Special sealants with international patents are used to guarantee water tightness.

Various panel designs are used to design tanks of all capacities and dimensions.

Standardized parts are used for on-site installation so that materials can be brought into restricted areas for convenient installation.

Single panels are used for water tanks installed underground, while the insulated panels, which are single panel with insulation material compressed together, provide excellent insulation on water tanks installed outdoors.

| DESIGN PARAMETERS FOR SECTIONAL TANK | Requirements according to E23 standard |

|---|---|

| Tensile Strength | ≥70MPa |

| Flexural Strength | ≥100MPa |

| bending modulus | ≥7.0GPa |

| Barcol Hardness | ≥60MPa |

| Water Absorption | ≤1.0% |

| Fiberglass content | ≥25 25% |

| Light transmission | Nil |

| Outdoor weathering(Natural sunlight) | Stabilized |

| Toxicity | Nil |

| Micro biological growth | Nil |

All panels can be lifted by hand, with no special equipment required even where access is difficult, and installation can progress quickly and efficiently.

SMC water tank is a popular solution for water storage due to its strength and lightweight nature. The SMC panel tank design allows for easy assembly and customization based on capacity needs. An SMC tank offers excellent durability and is resistant to corrosion, making it ideal for both industrial and residential applications. Many facilities choose SMC panel tanks because they can be easily transported and installed. The combination of GRP SMC panel tanks brings the benefits of both materials, offering superior performance in harsh environments. A panel tank structure is modular, allowing flexibility in design and installation. For larger projects, a panel water tank is often the preferred option as it provides scalable water storage solutions.SMC panel water tanks are especially suited for environments where hygiene, durability, and ease of installation are critical requirements.